4 point bend testing machine for glass|(PDF) Studies on determining the bending strength of thin : ODM The 4 point bend fixture for glass testing allows for the testing of glass samples up to 30cm x 30cm. It features 3 articulating and rolling anvils which utilize needle roller bearings for . Resultado da Screenshots. Yusuke Urameshi was a normal middle school punk until he was hit and killed by a car, while saving a child. His selfless action earned him the right to gain his life back and serve as a detective of the spirit world, keeping the world of the living safe from a myriad of demons.

{plog:ftitle_list}

WEB18 de jan. de 2024 · Reislin is an exciting and vibrant OnlyFans creator, offering her fans a variety of exclusive content. With 894 posts and over half a million likes received, she knows how to keep her audience engaged with her sexy and sultry personality. Reislin offers subscribers the opportunity to chat one-on-one for an intimate and personal experience.

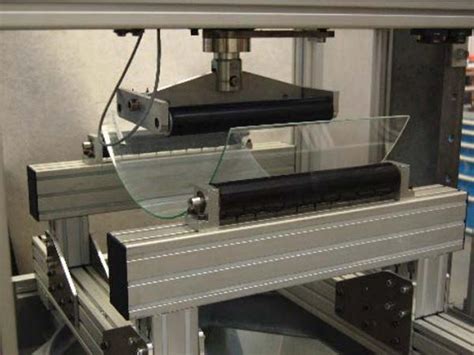

The 4 point bend fixture for glass testing allows for the testing of glass samples up to 30cm x 30cm. It features 3 articulating and rolling anvils which utilize needle roller bearings for .

Special testing machine for glass testing - Bending test according to DIN EN 1288 - Stamp pressure test according to ISO 614.more.

Holloway Control Systems latest bespoke machine is a 4-point glass testing rig. Designed to apply up to 2.5 Tonnes of pressure (25Kn of Force) to various thi.Universal Grip offers a fully articulating 4 point bend fixture for performing this test. The contact spans are also extra wide so that they can contact a large area on the sample. UGC can offer . Research has shown that the general approach to determine the bending strength of thermally curved glass with the aid of the four-point bending test for flat glass according to EN 1288-3 is applicable.ADMET bend fixtures are configured for 3-point and 4-point bend testing and are available in a variety of force capacities, support types, and span lengths. Model selection is often based on the size of the test specimen, expected .

Thermally Curved Glass

The inspekt S 50 test machine enables both 3-point and 4-point bending tests. Operational safety devices for safe material testing. If a glass breakage should result during material testing, this will be disposed of in an integrated .

The four point bending test is one of the most commonly used and standardised tests to determine the mechanical properties of materials. For its use on float glass there are both the ASTM C158-02R17 and European EN 1288-3:2001 standards. However when testing float glass the results tend be a statistical muddle. This impacts the reliability of the design strength .This test is performed on a universal testing machine (tensile testing machine or tensile tester) with a 3 point or 4 point bend fixture. The key analysis when performing bend testing are: Flexural Modulus – This measures the slope of .

For this reason, the four-point flexural test was developed. The single loading pin is just substituted by a double pin. Between these points there is a shear force-free range with a constant bending moment. Figure: .Bending tests on glass in accordance with the four-cut process. Special safety glass is often used in construction, for example in high-rise buildings. In order to guarantee high material quality here, special bending tests must be carried out beforehand. The inspekt S 50 test machine enables both 3-point and 4-point bending tests.

Special testing machines

1.2.5 Bending test. The three-point as well as four-point bending tests are conducted for measuring the deflection and bending strength of fiber-reinforced polymer plastics. . The loads may be applied manually by hanging weights on the beam or by a testing machine. Deflections are measured by a dial gauge placed underneath the beam. From the .

Fam and Rizkalla [24] have conducted four-point bend tests on monolithic and laminated glass panes. Jalham and Alsaed [25] and Bati et al. [26] have investigated the effect the different . ASTM C1161 bend testing fixture. Image Credit: Admet, Inc. ASTM C158 Bend Testing – Glass. ASTM C158 is of use in finding the modulus of rupture in bending, defined as the maximum tensile or compressive stress’ value (whichever causes failure) of glass and glass-ceramic samples. There are two ways of testing in ASTM C158:354 T. Peters et al. Fig. 1 Test setup schematic given by EN1288-3 bB ke Fmax 3(L s L b) 2Bh2 + bG (1) with the stress from self-weight bG: bG 3 gL2 s 4h (2) and with the glass width B and the . The two common types of bend fixtures are three-point and four-point bend fixtures: (1) Three-point bend fixtures: Configuration of flexural strength testing where a specimen is loaded at a .

Glass testing: 4

Glass Fiber Reinforced Polymer (GFRP): Used widely in marine, aircraft, and construction. Typical values: Young’s Modulus ~45 GPa, Tensile Strength ~1200 MPa, Elongation ~2.5%. . A bend test is performed using a universal testing machine or a specific bend testing machine. The test specimen is placed on the supports and a force is applied .Such materials may be more suitable for 4-point bend testing in accordance with ASTM D6272. Differences between ASTM D790 and ISO 178. ASTM D790 is very . ASTM D790 testing can be done on either a tabletop or floor model universal testing machine with a variety of accessories that can be configured to optimize your testing. Because every .

The 250 kN flexure fixture can perform 3-point flex / bend tests on specimens with a maximum width of 100 mm. A 4-point bend conversion kit is available. Lower span adjustable from 10 - 600 mm. Learn More. . The mini flexure fixture is designed for three-point bend or flexure testing of smaller components and specimens, where the specimen is . In a 4-point bending test, also known as a flexural test, the test specimen is placed on supports at two opposite ends, and force is applied at two intermediate points, causing the specimen to bend into a ‘U’ shape. . and 5% glass-fiber demonstrates a flexural strength of 32 MPa. This indicates its ability to withstand bending and torsion .

Bend Testing Equipment Guide; 3 and 4 Point Bend Testing of Semiconductor Devices; Fiber-Reinforced Concrete Testing: Design Changes in ASTM C1609 Equipment; Performing ASTM C1609 on an ADMET eXpert 2655 Universal Testing Machine; How to Perform an ASTM D790 Plastic Flexural 3 Point Bend Test; How to Perform a 3 Point Bend Test on a Universal .

Mach-1 – 3-point or 4-point Bending Test MA056-SOP11-D v1 BMMT CC#2016-001 BMMT QF4.02.01 v1 CONFIDENTIAL - UNCONTROLLED UNLESS OTHERWISE SIGNED AND/OR STAMPED Page 2 / 9 . For example, the stop criteria for a microscope glass slide would be 1000 gf. 8.13 Perform the following test sequence to perform the bending test: Functions . EN1288-3 (Glass in building—Determination of the bending strength of glass—Part 3: test with specimen supported at two points (four point bending), 2000) describes the four point bending test . Research has shown that the general approach to determine the bending strength of thermally curved glass with the aid of the four-point bending test for flat glass according to EN 1288-3 is .Or, it may involve bending a material until the material experiences a break and determining both the load and deflection required to initiative the break limit. Typical graph showing 3-point bend strength test: We provide force measurement instruments and materials testing machines for bending tests such as 3-point and 4-point bend.

The 250 kN flexure fixture can perform 3-point flex / bend tests on specimens with a maximum width of 100 mm. A 4-point bend conversion kit is available. Lower span adjustable from 10 - 600 mm. Learn More. . The mini flexure fixture is designed for three-point bend or flexure testing of smaller components and specimens, where the specimen is .Single-edge notch-bending specimen (also called three-point bending specimen) for fracture toughness testing.. The fracture toughness of a specimen can also be determined using a three-point flexural test. The stress intensity factor at the crack tip of a single edge notch bending specimen is [3] = [() / / + / / + /] where is the applied load, is the thickness of the specimen, is .The most common flexural testing of plastics, polymer composites, and large fiber-reinforced plates involves three-point and four-point bend testing according to ISO 14,125, ISO 178, ASTM D 790, and ASTM D 6272 to ensure suitability under various conditions for better insight into their properties and to ensure that they are suitable for the .Product Description. Glass Four-point Bending Tester . Usage . This tester is applicable to analysis and research of static physical performance test on phone glass,tablet computer glass,liquid crystal glass,touch sensor glass,toughened glass with three-point,four-point bending and elongation test;can do experiments according to International standard like .

Determination of the bending strength of glass via four point

Special testing machine for glass testing - Bending test according to DIN EN 1288- Stamp pressure test according to ISO 614Further information at: https://ww.Glass and Ceramic bend testing is usually performed on a square specimen. The specimens can be larger, such as 10x10 inches or more. For information on the exact size of the samples, please read the ASTM publication and refer to test method A or B. Solution: Universal Grip offers a fully articulating 4 point bend fixture for performing this .

Universal testing machine load frames come in single or dual column configurations and are available in force capacities up to 2,000 kN. . Wood and composites are most commonly tested with the 4-point bend test. The 4-point test requires a deflectometer to accurately measure specimen deflection at the center of the support span. Test results .

From the presented testing and analysis several comments can be offered. The Weibull moduli obtained from the 4-point bending tests are generally lower than from the 3-point bending tests. This could be because the 4-point bending test subjects a larger volume of the specimen to tension compared to the 3-point bending test.TestResources is a manufacturer & provider tensile, compression, bend, fatigue testing machines and equipment for testing different materials and products. . Ceramics & Glass; Composites; Metals & Metal Products; Paper & Paper Products; Plastics; Reinforced Concrete; Flexible Foam; Rubber & Elastomer; Textiles; Wood & Wood Products;

Determination of Bending Tensile Strength of Thin Glass

Bend Fixtures

WEBRatings and Reviews for bbrbet03 - WOT Scorecard provides customer service reviews for bbrbet03.com. Use MyWOT to run safety checks on any website.

4 point bend testing machine for glass|(PDF) Studies on determining the bending strength of thin